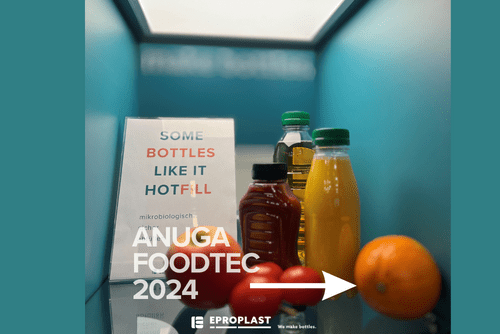

Hot filling in PET bottles is a safe filling technology that has been known for many years. Hot filling allows fruit juices, among other things, to be filled in a microbiologically safe way.

Our HOTFILL (HF) bottle series are suitable for filling food at temperatures of up to 87° Celsius.

In the PET hotfill blow moulding process, the plastic is heated to temperatures of up to 150° C in the blow mould. This causes crystallisation in the molecular structure. This crystallisation makes it possible to fill hot liquids without the bottle shrinking in an uncontrolled manner.

Some bottles like it hotfill!

- paneless PET hotfill technology

- PET standard hotfill technology

- for filling up to 87 ° hot products

- microbiological | safe | filling

- up to 50 % rPET possible

Als PET-Experte haben wir uns auch auf die Hotfill-Verfahren und Techniken spezialisiert, so dass wir Ihnen beide Hotfill-Verfahren anbieten können. Paneless-Hotfill und Standard-Hotfill.

Both processes offer different advantages and properties:

Advantages of Paneless Hotfill technology

SMOOTH EXTERIOR SURFACES

SIMPLE LABELLING

LOW BOTTLE WEIGHT

GREAT DESIGN FREEDOM

OPTICS LIKE A COLD ASEPTIC BOTTLE

Properties of the standard hotfill technology

MOSTLY SLEEVED

HIGHER BOTTLE WEIGHT

Conventional PET hotfill bottles are designed with so-called panel or ring structures to compensate for the volume contraction of the product after cooling.