EPRO Quality

Quality

Quality

We use state-of-the-art measuring and analysis techniques to ensure that our PET bottles and PET containers are subject to permanent control.

HOW DO WE WORK?

DEVELOPMENT & DESIGN

"The hardest part of having an idea is not having it, but recognizing if it's a good one." - Chris Howland

With innovative and outstanding design, we give our customers the decisive competitive edge in a highly competitive market. By working closely with creative designers, institutes, universities and technical colleges, we can quickly and easily turn your design ideas into marketable Products Our creative, innovative and practical solutions are one of the decisive criteria for our customers to do business with us.

DESIGN, DEVELOPMENT & MOULD MAKING

One-stop shopping - Kompetenz & know-how rund um Kunststoff-Verpackungen

Ein herausragender Service und ein absolutes Alleinstellungsmerkmal von EPROPLAST ist unser One-stop shopping Service! An absolute plus point, after all, at EPROPLAST, design and development as well as mold making and production go hand in hand.

In short, the complete service from a single source! With only one contact person, we offer our customers a compact service to develop and produce new and individual PET packaging. The time and thus also cost savings are clear advantages for our customers.

To this end, we support our customers as an innovative and reliable partner with the know-how gained from over 25 years of experience in PET development and production.

MOLD DESIGN

SPECIALIZATIONS

In addition to molds for all common industries, our mold making division specializes in blow molds as well as applications in multi-component technology.

FLEXIBILITY

The direct route to our mold making facility ensures a high degree of flexibility in order to be able to react to individual customer requirements and implement them quickly.

PRODUCTION

Ob gross oder klein… PET-VERPACKUNGEN IN JEDER GRÖSSE

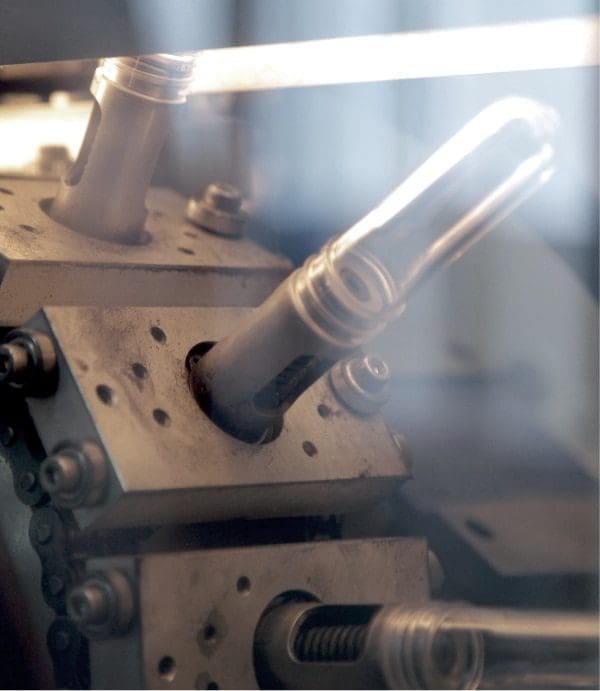

EPROPLAST offers a production capacity of more than 100 million bottles per year. The volumes of PET packaging we produce range from 20 to 1000 ml. The 1-stage injection stretch blow molding lines and 2-stage stretch blow molding lines we use represent the most modern technology for the production of PET bottles and PET containers.

- COSMETICS

- DETERGENT, CHEMICAL

- HONEY, MUSTARD, SAUCE

- LIQUOR

- FRUIT JUICES

- DAIRY AND MIXED DRINKS

- VINEGAR & COOKING OIL

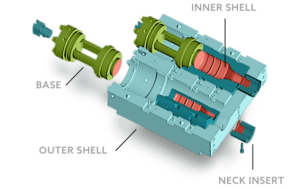

ECOSHELL® - das Werkzeugsystem für individuelle Kundenformen

With innovative and outstanding design, we give our customers the decisive competitive edge in a closely contested market.

Through intensive collaboration with creative designers, institutes, universities and technical schools, we can quickly and easily transform your design ideas into saleable products. The creative, innovative and practical approaches to solutions are one of the decisive criteria for our customers to do business with us.

PREFORM PRODUCTION

We produce our own preforms for our PET packaging on the latest injection molding equipment. The reason: We thus achieve the highest possible level of quality assurance and product control.

Process control

QUALITY - OUR COMMITMENT TO YOU

We use state-of-the-art measuring and analysis techniques to ensure that our PET bottles and PET containers are subject to permanent inspection.

Not only do our employees with their trained eyes detect sources of error, but our plants are also equipped with automated testing facilities.

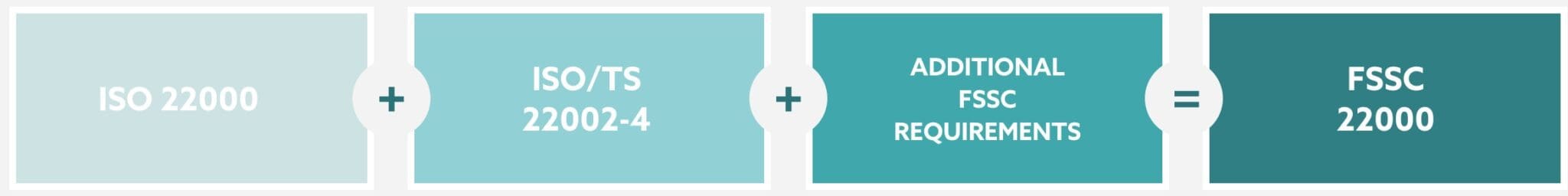

FSSC 22000 - THE HYGIENE CONCEPT

Customers who place particularly high demands on cleanliness and hygiene are at the right address at EPROPLAST. With the FSSC22000 certification (Food Safety System Certification) of our company, EPROPLAST GmbH sets new standards in the field of hygiene and cleanliness.

FSSC 22000 - certification

The Food Safety System Certification 22000 (FSSC 22000) offers a complete certification Scheme for the auditing and certification of Food Safety Management Systems (FSMS). It also offers certification for combined FSMS and Quality Management Systems (FSSC 22000-Quality). Developed through extensive and open consultation with many global stakeholders, the Scheme uses international and independent standards such as ISO 22000, ISO 9001, ISO/TS 22003, and technical specifications for sector-specific Pre-Requisite Programs (PRPs), such as ISO/TS 22002-1.

The Scheme provides a certification model that can be used in the whole food supply chain. It can cover sectors where a technical specification for sector PRPs has been realized. FSSC 22000 follows the food chain category description as defined in ISO/TS 22003.

The Scheme documents contain the requirements for organizations in the food and feed supply chain to gain certification. They shall be used by the applicant organization to assess, develop, implement, and improve its food and feed safety management system prior to application for certification. (source: fsc22000.com)